28 October 2020

Mintronics provide a helping hand for CAD designers

Darlington-based 3D software company Mintronics was founded in 2008, in the midst of the last major global recession triggered by the sub-prime mortgage crisis. Like many organisations around the world, Mintronics has been able to achieve rapid growth in business during tough trading conditions by reaching out to offer support to customers when they need it most. Mintronics is the UK distributor for Alibre 3D Design CAD software which is developed in Texas, USA. Alibre offers regular updates and enhancements for an affordable per-seat pricing with features to match or exceed the market leading CAD software providers. Since the start of the global Coronavirus pandemic, Mintronics has been helping existing and new clients to control their costs and enhance their designs with new versions of the Alibre software. Especially for small businesses, CAD software monthly subscription fees can be a major ongoing financial burden, which has a dramatic negative impact on profitability when there is a decrease in revenue for a number of months.

Darlington-based 3D software company Mintronics was founded in 2008, in the midst of the last major global recession triggered by the sub-prime mortgage crisis. Like many organisations around the world, Mintronics has been able to achieve rapid growth in business during tough trading conditions by reaching out to offer support to customers when they need it most. Mintronics is the UK distributor for Alibre 3D Design CAD software which is developed in Texas, USA. Alibre offers regular updates and enhancements for an affordable per-seat pricing with features to match or exceed the market leading CAD software providers. Since the start of the global Coronavirus pandemic, Mintronics has been helping existing and new clients to control their costs and enhance their designs with new versions of the Alibre software. Especially for small businesses, CAD software monthly subscription fees can be a major ongoing financial burden, which has a dramatic negative impact on profitability when there is a decrease in revenue for a number of months.

When times are hard, people often rally together to collaborate and help each other out. Rapid implementation of new tools and practices can help businesses survive and grow even when the environment is severely disrupted by global travel restrictions and market disruption.

Flexibility is important when faced with a drop in sales for regular products. The ability to design new products and bring them to market quickly can boost the performance of innovators to protect their business.

The ability to respond quickly with creative and pertinent designs has enabled a number of sheet metalwork companies to address the urgent needs of new products from ventilator housings, through sanitiser dispensers and point-of-sale partitioning, used to restrict virus transmissions. None of these products were in demand until March of this year. Time to market is critical for new product introductions and the process starts with design.

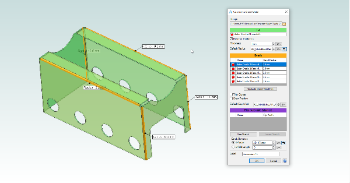

An example of how CAD can accelerate the job of the mechanical design engineer is the sheet metal module in Alibre Design Expert which allows manufacturing companies with laser cutting and press brakes to design 3D assemblies made from 2D sheet metal with a minimal number of operations. The enhanced snap function allows sketches to be turned into finished CNC programs rapidly and accurately using the extensive library of ready-to-use designs.

Specifically for sheet metal fabricators, Alibre comes with a “sheet metal” module that enables easy calculation of cutting paths allowing for bend allowances where parts are to be laser cut and then folded. There are two methods to achieve this, either using the K-Factor or the unfold length – these can be controlled globally or customised per bend as preferred. The tools for modelling in sheet metal can create multiple bends in a single operation using the contour and flange functions.

Specifically for sheet metal fabricators, Alibre comes with a “sheet metal” module that enables easy calculation of cutting paths allowing for bend allowances where parts are to be laser cut and then folded. There are two methods to achieve this, either using the K-Factor or the unfold length – these can be controlled globally or customised per bend as preferred. The tools for modelling in sheet metal can create multiple bends in a single operation using the contour and flange functions.

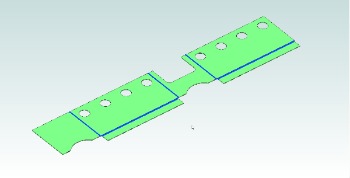

Starting from a 3D model, imported CAD data (in STEP or IGES format) can be transformed to flat sheet layouts using the comprehensive “Convert to Sheet Metal” function. In Figures 1 and 2, the 3D object has been converted to sheet metal and flanges and bend radii have been added.

In 2021, there is likely to be a new breed of start-up companies with people released from their previous employment seeking to set up a new design-led business, working from home and using 3D design to provide profitable products with minimum overheads. One of the significant overheads is running an office and having multiple and expensive seats for CAD design.

Licences from Alibre are significantly cheaper than the large CAD companies, and the licences are perpetual. Clients can choose to keep with the current software revision or buy a maintenance contract to upgrade to the latest software issue. If you choose to stick with the current software, there is no need to renew your licence monthly or annually – something that other companies enforce by rigid policies which penalise the buyer.

Comparing cost of ownership of Alibre software over a five year period, savings can be dramatic. A recent study showed the Alibre equivalent product saved companies up to 80% against the big CAD suppliers. Support from Mintronics in the UK allows very small companies the option of running lean design desks and gaining access to versatile CAD solutions at a price designed to make it accessible to companies of any size.

Images:

Fig. 1 – An imported 3D boiler cradle for a model engine is converted to cut lines, flanges and

folds using the Alibre Sheet Metal Module.

Fig. 2 – The part is converted to a flat profile prepared for laser cutting and folding.

- Contact Information

- Name: John Minto

- Email: business@mintronics.co.uk

- Website: www.mintronics.co.uk