21 April 2020

How Luxinar is helping the fight against coronavirus

Customers of Luxinar in the food and beverage and medical device industries are experiencing an increasing demand for their products in relation to COVID-19 which has led to increased orders for Luxinar’s CO2 laser sources. Other customers are ramping up or switching production to respond to the increased demand for coronavirus-related products; these include the 24-hour injection moulding facility of Hull-based Advanced Plastics and the manufacturing sites of a global cleaning product supplier.

Customers of Luxinar in the food and beverage and medical device industries are experiencing an increasing demand for their products in relation to COVID-19 which has led to increased orders for Luxinar’s CO2 laser sources. Other customers are ramping up or switching production to respond to the increased demand for coronavirus-related products; these include the 24-hour injection moulding facility of Hull-based Advanced Plastics and the manufacturing sites of a global cleaning product supplier.

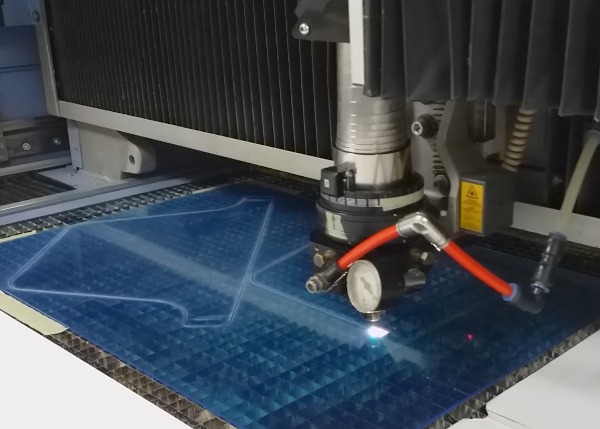

A major partner of Luxinar, employer-led school Ron Dearing UTC has supplied Perspex sheets to Luxinar so that colleagues in the company’s applications laboratories can laser cut and engrave visors. This is in support of the Hull school’s initiative to create face shields for key healthcare workers battling coronavirus.

Also, in response to the UK’s National Health Service (NHS) call for 3D printed parts, colleagues at Luxinar are using printers that they have either borrowed or made in-house to produce face masks for NHS health workers throughout the country. Luxinar is supplying the materials and the 3D printed parts are being sent to a company for assembly and sterilisation before being passed to the NHS distribution hub.

Darren Taylor, Senior Manufacturing Engineer at Luxinar and in charge of the project said, “I have been astounded by the response and support I have been given through this activity. It really makes it all worthwhile.”

- Contact Information

- Name: Joanna Houldridge

- Email: joanna.houldridge@luxinar.com

- Website: www.luxinar.com