23 October 2018

Automation made simple as ACSYS introduce new PIRANHA Roboshift

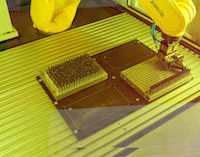

Offering increased throughput and shorter cycle times, the new PIRANHA Roboshift is equipped with an integral six-axis robot for faster loading and unloading of components. Automated laser processing can be achieved using the robot arm to pick and place parts from a tray or stack, presenting them for laser processing, then returning the finished parts to the output stock, freeing up the machine operator for other tasks. Laser marking, etching or engraving of parts in virtually any material is possible with any of the range of laser sources from ACSYS. Fitted with a powerful fibre laser as standard, there are options for advanced picosecond or femtosecond lasers where highest precision or ultimate quality “cold” laser processing is required.

Offering increased throughput and shorter cycle times, the new PIRANHA Roboshift is equipped with an integral six-axis robot for faster loading and unloading of components. Automated laser processing can be achieved using the robot arm to pick and place parts from a tray or stack, presenting them for laser processing, then returning the finished parts to the output stock, freeing up the machine operator for other tasks. Laser marking, etching or engraving of parts in virtually any material is possible with any of the range of laser sources from ACSYS. Fitted with a powerful fibre laser as standard, there are options for advanced picosecond or femtosecond lasers where highest precision or ultimate quality “cold” laser processing is required.

Using the robot arm, the part can be rotated under the laser beam for cylindrical processing (either on the inner surface or outer surface) and accuracy is maintained by the excellent 0.01 mm repeatability of the robot positioning arm. Many applications in the jewellery, watchmaking, medical device and automotive industries can benefit from the greater productivity of this new system.

PIRANHA Roboshift can be used to handle parts up to 7 kg and the Live Adjust System (LAS) adds a camera vision system for live preview to verify the set-up – making adjustments to the marking position based on the actual orientation and position of the part on the fly.

Example parts which are ideally suited to the PIRANHA Roboshift include ball and slide bearings, drilling and milling tools, medical implants, surgical instruments, precious metal rings and many other small components that need either permanent laser marking or deep 3D engraving by laser.

“The new PIRANHA Roboshift delivers outstanding results in continuous or batch production –rising to the challenges of precision and speed”

- Contact Information

- Name: Jonathan Magee

- Email: info@acsyslaser.co.uk

- Website: www.acsyslaser.co.uk