4 May 2018

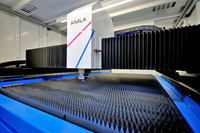

Sheet metal fabricator buys second Kimla from MBA Engineering

Sheet metal fabrication specialist, Concept Metal Products Ltd, has invested in a second, Kimla fibre laser system from supplier MBA Engineering, after experiencing substantial increases in production from its first machine. After installing a bespoke, 10m x 2m Kimla Powercut 4kW Fibre Laser in early 2017, Concept Metal Products was so impressed not only with the speed and precision of the machine, but also the resulting cost savings, that it has now called upon MBA Engineering to provide a second system.

Sheet metal fabrication specialist, Concept Metal Products Ltd, has invested in a second, Kimla fibre laser system from supplier MBA Engineering, after experiencing substantial increases in production from its first machine. After installing a bespoke, 10m x 2m Kimla Powercut 4kW Fibre Laser in early 2017, Concept Metal Products was so impressed not only with the speed and precision of the machine, but also the resulting cost savings, that it has now called upon MBA Engineering to provide a second system.

To boost the company’s fabrication capabilities, Concept Metal has invested in a Kimla Powercut LF2040 6kW, which MBA Engineering – UK's distributor of Kimla fibre laser cutting equipment – installed and set up. Speaking about the new installation, Dean Barnard, General Manager at Concept Metal Products, said: “After having our original Kimla system installed, we were amazed by the performance of the machine. The efficiency and precision of the equipment is something we haven’t experienced before with competitor models, while the cost savings have been far more significant than we anticipated.

“Following the success of this first machine, the obvious choice for us was to install a second system to further enhance our capacity and production capabilities."

Bradley McBain, managing director at MBA Engineering, said: “We pride ourselves on delivering advanced, cost-effective metal fabrication solutions. Kimla is one of the most innovative laser system manufacturers out there – the team combines state-of-the-art technology with outstanding customer service, an ethos that we echo."

- Contact Information

- Name: Bradley McBain

- Email: bradley.mcbain@mba-eng.co.uk

- Website: www.mba-eng.co.uk